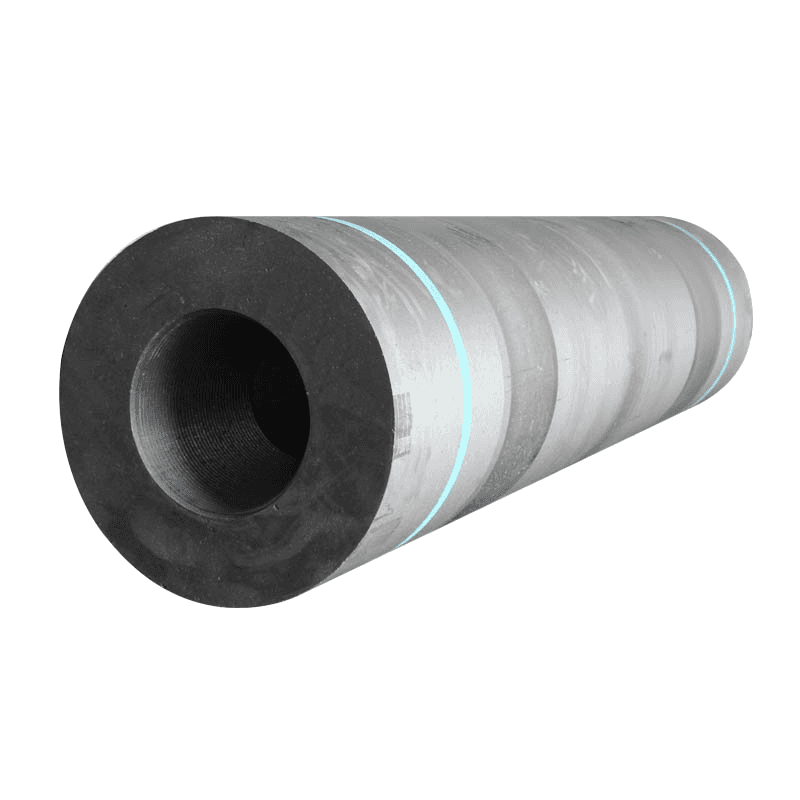

Ultra High Power Graphite Electrodes: The Key to Increased Steel Production

1, the use of graphite electrode

(1) For electric arc steelmaking furnace: electric furnace steelmaking is a large user of graphite electrodes. The output of electric furnace steel in China accounts for about 18% of the output of crude steel, and the graphite electrode used in steelmaking accounts for 70% to 80% of the total amount of graphite electrode. Electric furnace steelmaking is to use graphite electrode to introduce current into the furnace, and use the high temperature heat source generated by the arc between the electric extreme part and the charge to control the smelting.

(2) For the mineral thermal furnace: the mineral thermal furnace is mainly used for the production of industrial silicon and yellow phosphorus, etc., which is characterized by the lower part of the conductive electrode buried in the charge, forming an arc in the material layer, and using the heat energy emitted by the resistance of the charge itself to heat the charge, which requires a higher current density of the mineral thermal furnace requires graphite electrodes, such as the production of 1 silicon needs to consume about 100kg of graphite electrodes, About 40kg of graphite electrodes are consumed for every 1t of yellow phosphorus produced.

(3) For resistance furnace: the production of graphite products graphitization furnace, melting glass furnace and the production of silicon carbide with the electric furnace, etc., are resistance furnace, furnace material is both heating resistance and heated object, usually, conductive graphite electrode embedded in the resistance furnace end of the furnace head wall, used here for graphite electrode discontinuous consumption.

(4) For the preparation of special-shaped graphite products: the wool of the graphite electrode is also used for processing into various yard, mold, boat and heating body and other special-shaped graphite products. For example, in the quartz glass industry, for every 1t of electric melting tubes produced, 10t of graphite electrode is required; For every 1t quartz brick produced, 100kg of graphite electrode blank is consumed.

2, graphite electrode performance

(1) Strong electrical and thermal conductivity

(2) High thermal vibration resistance and chemical stability

(3) lubricity and wear resistance.

(4) processing is easier, EDM (electric spark) metal removal rate is high, graphite loss is small.

(5) The specific gravity of graphite is 1/5 of copper, and the weight of the same volume of graphite is 5 times lighter than copper. The large electrode made of copper is very heavy, which is very unfavorable to the spindle accuracy of EDM machine tool during long-term EDM. Graphite does not, and it is very safe to handle

(6) Graphite can have a high processing speed, and the processing speed of general graphite is 3-5 times faster than that of ordinary metal. And choose the appropriate hardness of the tool and graphite, can reduce the wear of the tool and the loss of the electrode.

Recent Posts

undefined

Quote Now

Quote Now